Back to list ›

Hot Strip Mill - Plate Mill

- Centering control

- Rolls gap / guides control

- Tracking

- Cropping control

From the exit of reheat furnace to down coiler, DELTA hot metal detectors, infrared scanner and laser measuring sensors are extensively used for detection, edge positioning and measurement. They are able to work with high accuracy and reliability in the harsh environment of hot mills: high ambient temperature, heat radiation, steam, water, dust…

Rougher area

- Tracking of the product with scanning HMD Rota-Sonde DC.

|

Detection before shear

- IRIS, for detection below the table when the environmental conditions, water and steam, makes the detection from the top difficult.

|

|

Centring

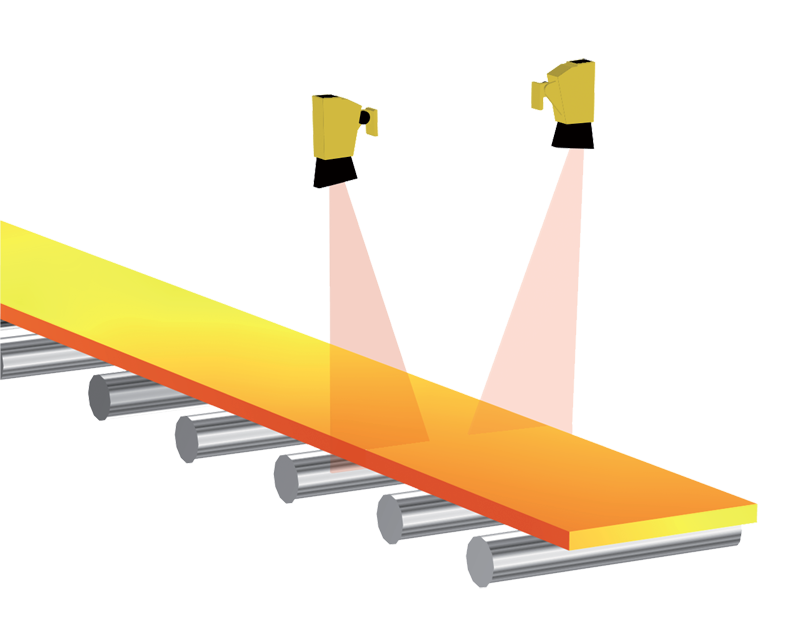

- Strip centring with Infrared Loop Scanner Rota-Sonde TS.

|

Finishing and coiler area

- Detection of the head and tail of the strip before coiler with high power Optical Barriers VE/VR or high sensitivity scanning HMD Rota-Sonde DC.

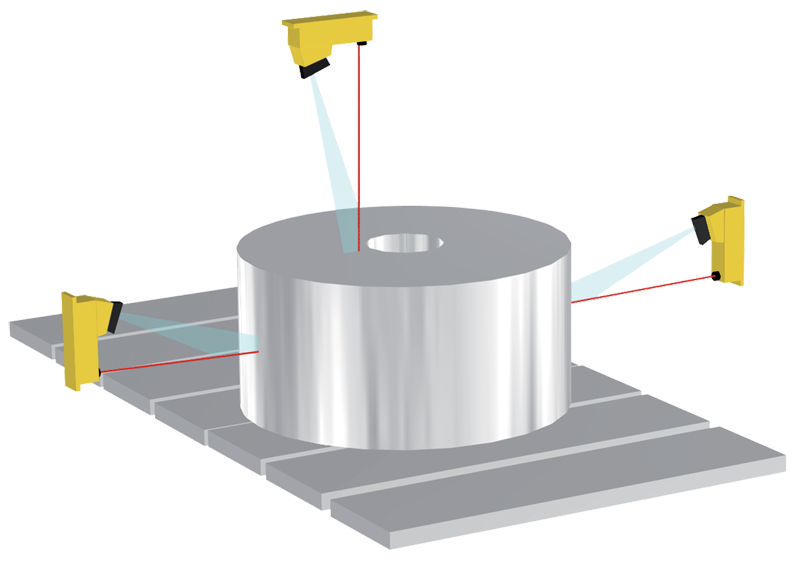

Coil transfer

- Coil dimensions and centring with Laser Sensors Trilas TL.

‹ Back to list